Styrene Void Former Slips Through the Cracks of Pollution Policy

Sustainable building practices are the reality of future construction. If you are not adopting sustainable practices, prioritising the principles of the circular economy and advancing on your sustainability journey, you are being left behind.

But what is a truly sustainable building practice? Once marketed as a sustainability solution, polystyrene void formers, commonly known as wafflepod now stand in direct contradiction to these efforts. Not only can these styrene products break apart on site during installation, they blow into the local environment and become persistent pollutants in our waterways. Their cradle-to-grave impact tells a very different story.

The ACT Government has taken commendable steps in the light of a global environmental crisis. Legislative actions like the “Circular Economy Act 2023” represent the territory’s commitment to continuing the phase-out of single-use plastics such as expanded polystyrene food and beverage containers. However, in just one house slab, the construction industry continues to bury the equivalent of 43,956 styrene cups beneath concrete, skirting condemnation. It is estimated that expanded polystyrene takes over 500 years to decompose, and the harmful products we bury today will continue to be a problem in our environment for nearly 20 generations.

All of Australia’s environmental ministers have agreed to work with the private sector to achieve a circular economy by 2030, so designing for disassembly is going to become increasingly important in the coming years.

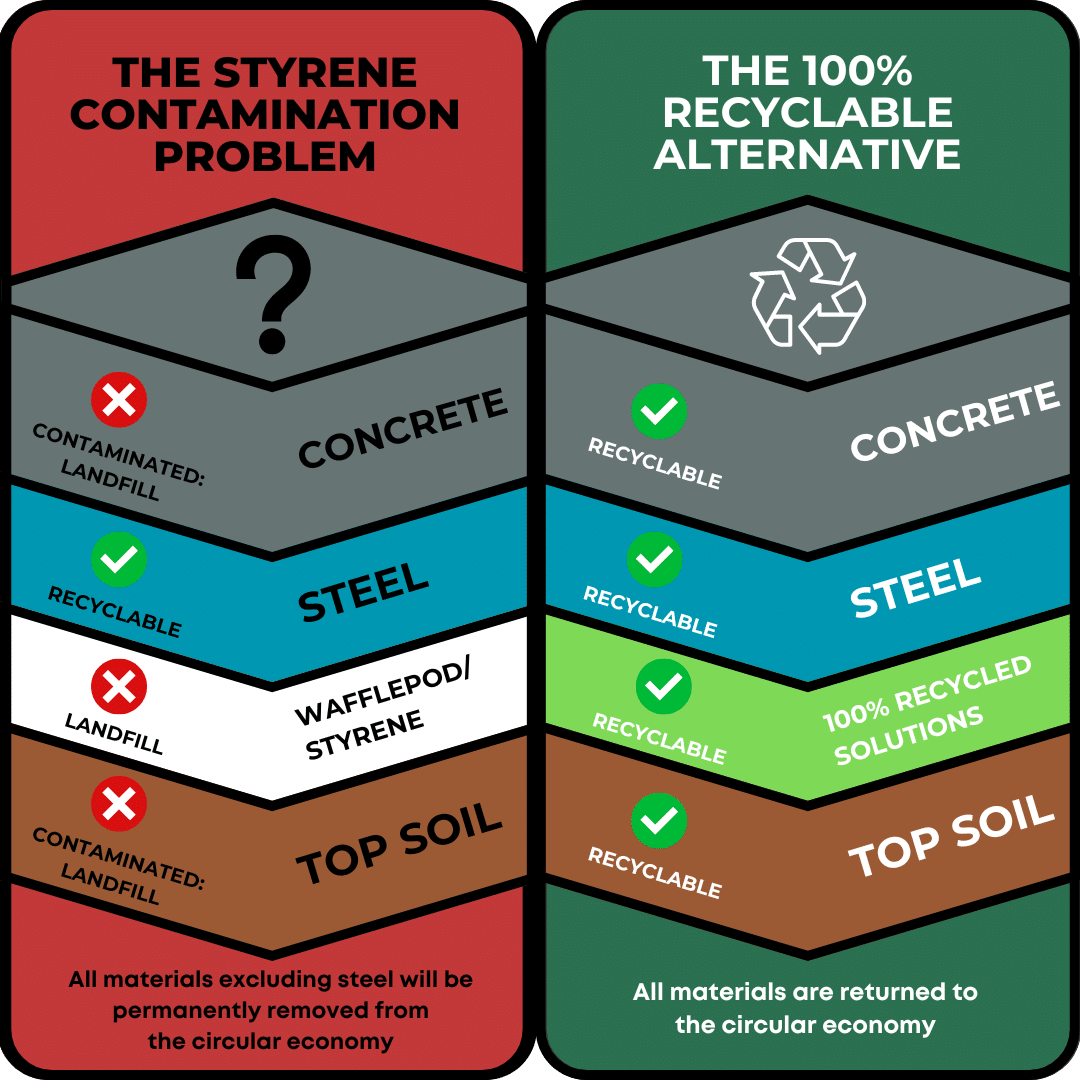

In a typical demolition of a concrete foundation, the entire slab can be sent for recycling and has many applications such as creating aggregate, backfill, road base, landscaping gravel, and more. The demolition of a slab that has been formed with wafflepod is “comparative to breaking open a beanbag with an excavator”.

All concrete is and topsoil are permanently contaminated and are unable to be recycled, expanding on the already 76 million tonnes of waste that the construction industry generates in Australia annually. Given the high CO2 emissions associated with its production, diverting concrete from the recycling stream and sending it to landfill is deeply irresponsible.

Given the high CO2 emissions associated with its production, diverting concrete from the recycling stream and sending it to landfill is deeply irresponsible. This completely removes concrete from the circular economy and prevents us from reutilising one of the most carbon intensive materials on the planet, failing future generations who will inherit the consequences.

The reality is if we want a sustainable construction future, we can’t keep doing what we’ve always done.

So what can you do?

There now exist many cost effective solutions that can create efficiencies in your builds and also provide a sustainable solution to traditional problems. Our designers and specifiers from across the construction industry need to continue to lead by example, adopting , specifying, and promoting the use of sustainable solutions. By doing so, they not only adhere to best practices but also drive the change need while boosting the demand for greener products, encouraging manufacturers to innovate further.

Simultaneously, it is crucial for end-users, including homeowners, builders and developers, to prioritise sustainability in their projects and insist on using materials that have lower environmental impact.

If we are truly committed to the circular economy and sustainable building practices, it is essential that our policymakers make meaningful change but enforce regulations and legislation that phase out this environmentally damaging construction material and support the industry’s transition to sustainable alternatives. By implementing stringent regulations and providing incentives for using the commercially available 100% recycled alternatives, our Government can significantly influence the industry’s environmental footprint.

We already know this is an issue, we already know we can do better, we already have more cost effective sustainable alternatives, but we aren’t making the easy impactful changes. Let’s not keep burying our heads — and this problem — in the ground. As an industry and a society, let’s commit to a legacy of sustainable construction. Let us create an industry that values building for the future.