Concrete Accelerators Explained

Most people working around concrete have heard of accelerators but what exactly do they do?

Concrete is an incredible building material: strong, durable, and versatile. However, when temperatures drop or you have a time critical job, sometimes the speed at which it sets and gains strength it isn’t fast enough. That’s where concrete accelerators come in.

What are concrete accelerators?

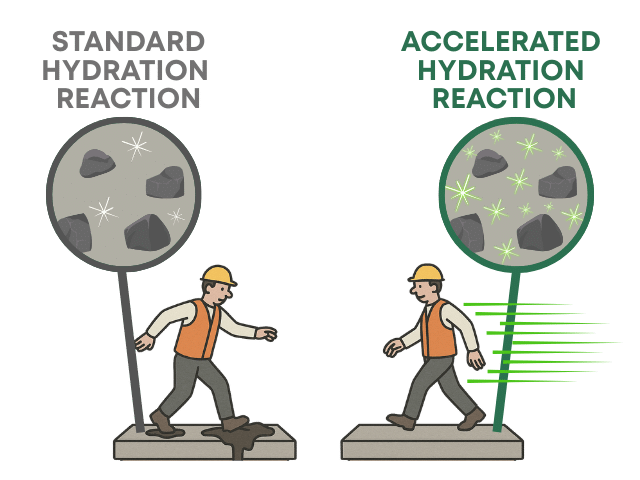

In simple terms, a concrete accelerator is an additive mixed into the concrete when the raw materials like cement, aggregate and water are loaded into the concrete truck (the batching stage). Its role is to speed up the chemical reactions that occur when cement and water combine, a process known as hydration. Faster hydration means quicker setting and early strength development.

Importantly, accelerators don’t sacrifice long term strength or durability. They simply help the concrete reach early age strengths faster, which can be crucial when strpping formwork, working in cold conditions, or opening a road to traffic sooner.

How do they work?

Cement hydration involves a series of chemical reactions that are responsible for concrete’s strength. Typically, there’s a short dormant (induction) period after mixing, where the reaction slows before ramping up again. Accelerators reduce the length of this dormant phase and increase the rate of early hydration reactions.

They do this by speeding up the dissolving of cement particles into the mix water, encouraging rapid formation of calcium silicate hydrate (C-S-H), the primary strength giving compound in concrete, and speeding up the formation of calcium hydroxide, which fuels further hydration.

Common chemical accelerators include calcium nitrate, calcium formate, and certain proprietary blends. Some, like those in the MasterSet range from Master Builders Solutions, are designed to work reliably across varying temperatures and mix designs, ensuring consistent early strength performance.

Why use accelerators?

“On site, time is money, so for many concreters and builders there are plenty of situations where accelerating concrete keeps the job moving without costly delays”

– Damian Ross, CE Construction Solutions

Some examples of when an accelerator would be used includes:

- Cold Weather Work: The lower the temperature, the more useful accelerators can be. Cold ambient temperatures slow cement hydration significantly. Accelerators help counteract this slowdown, increasing the turnaround from pour to loading and reducing the risk of damage from early-age freezing.

- Tight Schedules: Projects often require quick turnaround including early formwork removal and loading. Accelerators can reduce the initial set time significantly, saving up to 20-50% set time and canallow works to resume up to a day earlier.

- Precast Applications: Faster strength gain means quicker demoulding and higher production rates in precast plants.

- Early Traffic Loads: Roads and pavements (for example in airports or highways) sometimes need to open fast. Accelerators help concrete reach safe load-bearing strength sooner.

While accelerators are incredibly useful, choosing the right product and dosage is key. Overdosing or using the wrong type can affect the overall properties of the concrete, increase shrinkage, or interfere with other admixtures.

Builders should consider factors like cement type, ambient temperature, and required setting times when selecting an accelerator. Consulting with your concrete supplier or CE Construction Solutions to ensure your project is optimised with the right solution.

At the end of the day, concrete accelerators are a valuable tool in the builder’s toolkit, especially when the job demands speed without sacrificing quality. Whether battling winter conditions or racing against a tight schedule, accelerators help keep projects on track and concrete performance reliable.

Concrete Accelerator FAQ

Will using an accelerator weaken the concrete?

No, when used correctly, accelerators do not reduce the final strength of the concrete. They simply help it reach early strength faster.

Are accelerators safe to use with steel reinforcement?

Yes, as long as you choose a non-chloride accelerator. Chloride-based products can cause corrosion in steel reinforcement and should be avoided in structural work.

Will it change how I finish the concrete?

Maybe, the accelerated setting means finishing must happen sooner. Be ready to start earlier than you would normally expect in cold weather.

Can I use accelerators in hot weather?

In hot conditions, concrete already sets quickly, you’re more likely to use retarders instead to slow things down and allow more working time.

Do I need to change my mix design?

Not necessarily, but it’s best to consult with your concrete supplier to make sure your accelerator is compatible with your mix.

Are all accelerators the same?

No there are different types with different effects. Some are faster, some are designed for specific temperatures or mixes. Product selection matters.

Are accelerators expensive?

The cost varies depending on the product and dosage, but the time savings (in project delays, labour or equipment hire) often significantly outweigh the upfront cost.

Can I combine accelerators with other admixtures?

Yes, but check compatibility first. Using multiple admixtures (e.g. accelerators + water reducers or plasticisers) requires technical advice to avoid unwanted reactions.

Why doesn’t my concrete set faster with accelerator?

Accelerator alone might not be enough; producers design concrete for the slump required with a specific water content. If on site water is introduced into the mix to increase slump, that water needs to come out of the concrete before hydration starts and generally sits on the slab as Bleed. Add water on site at your peril.

Sometimes planning is better than “more accelerator”

AS 1379” requires that concrete temperatures at the point of delivery be within the range 5 to 35°C”. Planning a delivery that fits inside the above can help cold weather concrete perform onsite.